What we do

Our process

Consultation

Cake Industries prioritises early collaboration with designers, cost consultants, and main contractors to align vision, feasibility, and economics from the outset. Under a PCSA, Cake extends comprehensive pre-tender design advisory services, including 3D modeling, engineering analysis, and cost planning, ensuring all aspects of the project, from logistics to financials, are thoroughly prepared before proceeding.

Prototyping

Recognising the uniqueness of each project, Cake advocates for extensive prototyping, which includes sampling and full-scale models to ensure the final build meets their high standards. This phase fosters collaborative refinement between all project stakeholders.

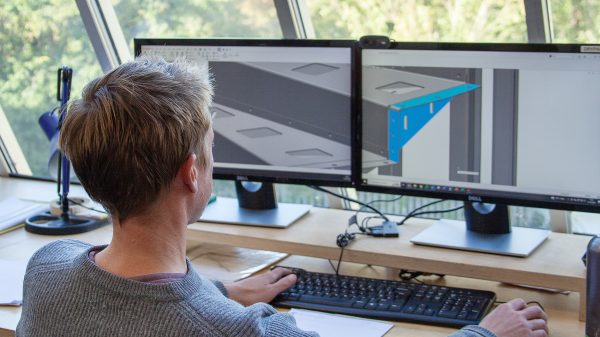

Design

Cake’s skilled in-house design team transforms initial sketches into detailed, fabrication-ready models using advanced 3D parametric software like SolidWorks, Rhino, and Grasshopper. This early engagement facilitates the creation of projects that are both aesthetically pleasing and cost-effective. Cake also offers standalone design commissions and third-party checks while incorporating sustainable practices to address the climate emergency.

Fabrication

Operating from its South London workshop, Cake handles a variety of bespoke projects, from staircases to structural steelworks and artistic installations. The team utilises a broad skill set and specialised machinery to meet rigorous standards. All structures, including staircases and steelworks, comply with UKCA marking to execution class 2 as required for the UK market.

Installation

Cake’s comprehensive installation services ensure that fabricated structures are seamlessly integrated into their final locations. Cake prepares meticulously, coordinating with logistics and other stakeholders, and the qualified installation team utilises bespoke methodologies tailored to each project. Cake manages everything from risk assessments to on-site finishing, ensuring top-quality results.

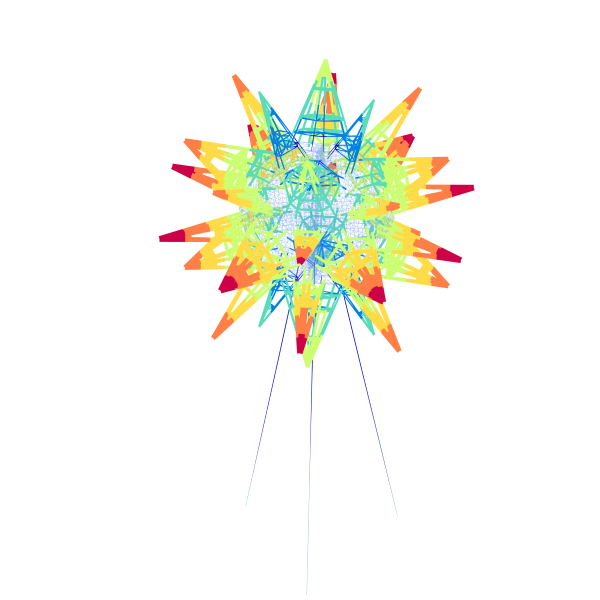

Structural Engineering

Cake Engineering provides structural consultancy services for projects of all sizes, with particular expertise in bridge design and independent checking. Led by David Knight, our team delivers structural design, specification, and compliance calculations for both private and public clients. Our portfolio includes everything from residential modifications to sculptures, highway structures, and award-winning footbridges.

Materials

Explore the meticulous process Cake Industries employs from initial consultation to final installation, ensuring precision and excellence in every project.

Steel

We work across mild, hardox, weathering and stainless steels, delivering both architectural and structural fabrication. With Execution Class 3 capability and a workshop set up for large-format work, we produce everything from fine details to heavy, long-span components.

Non-Ferrous

We fabricate in aluminium, brass, bronze and copper, delivering lightweight structures and high-finish elements. Specialist forming and polishing are carried out by trusted partners we’ve worked with for years to maintain consistent quality.

Timber

We work with hardwoods, softwoods and engineered timber, supported by strong in-house knowledge of joinery, material behaviour and buildability. All fabrication and assembly are carried out in our fully equipped timber workshop, enabling us to deliver complex structural or architectural elements and to integrate them cleanly with steel and other systems.

Other Materials

We coordinate complex, multi-material builds, ensuring glazing, composites, casts and metalwork integrate cleanly. Our material-centric approach and strong supply chain ensure interfaces are properly resolved and projects come together as one cohesive assembly.

Finishing

Our strength lies in understanding finishes, how they behave, what preparation they need, and which specialist process will achieve the intended outcome. We combine in-house work with trusted finishing partners, covering everything from galvanising and resin systems to timber staining, blackening and emerging processes.