© 2020 Cake Industries. All rights reserved.

Network Rail Bridge Competition

Cake Industries collaborated with CF Architects (http://cf-architects.com) to enter an international competition to design a concept for a new standard fully accessible pedestrian footbridges for the UK rail network. Our entry was shortlisted and exhibited at the Royal Institute of British Architects in Portland Place as part of the competition publicity.

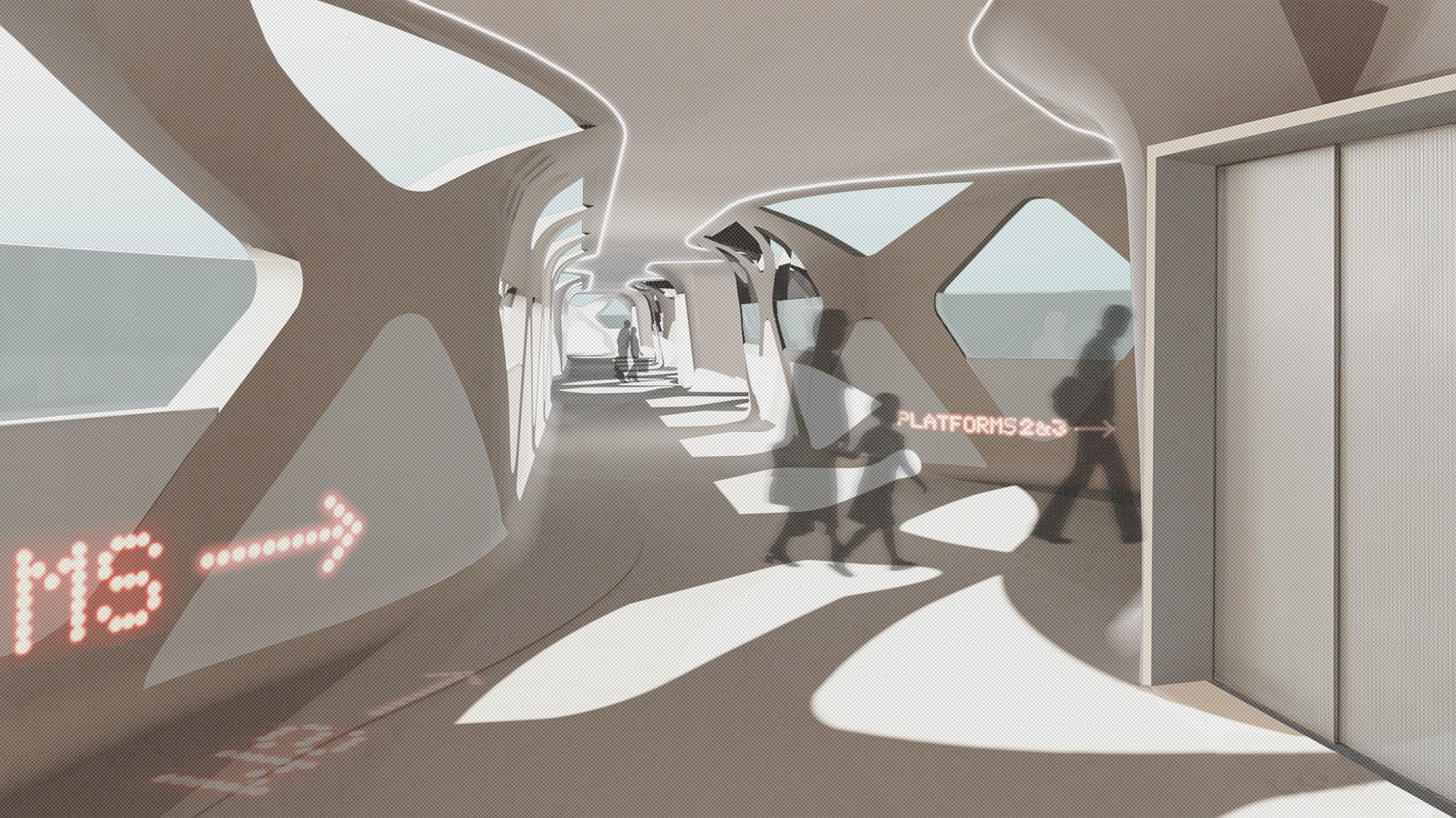

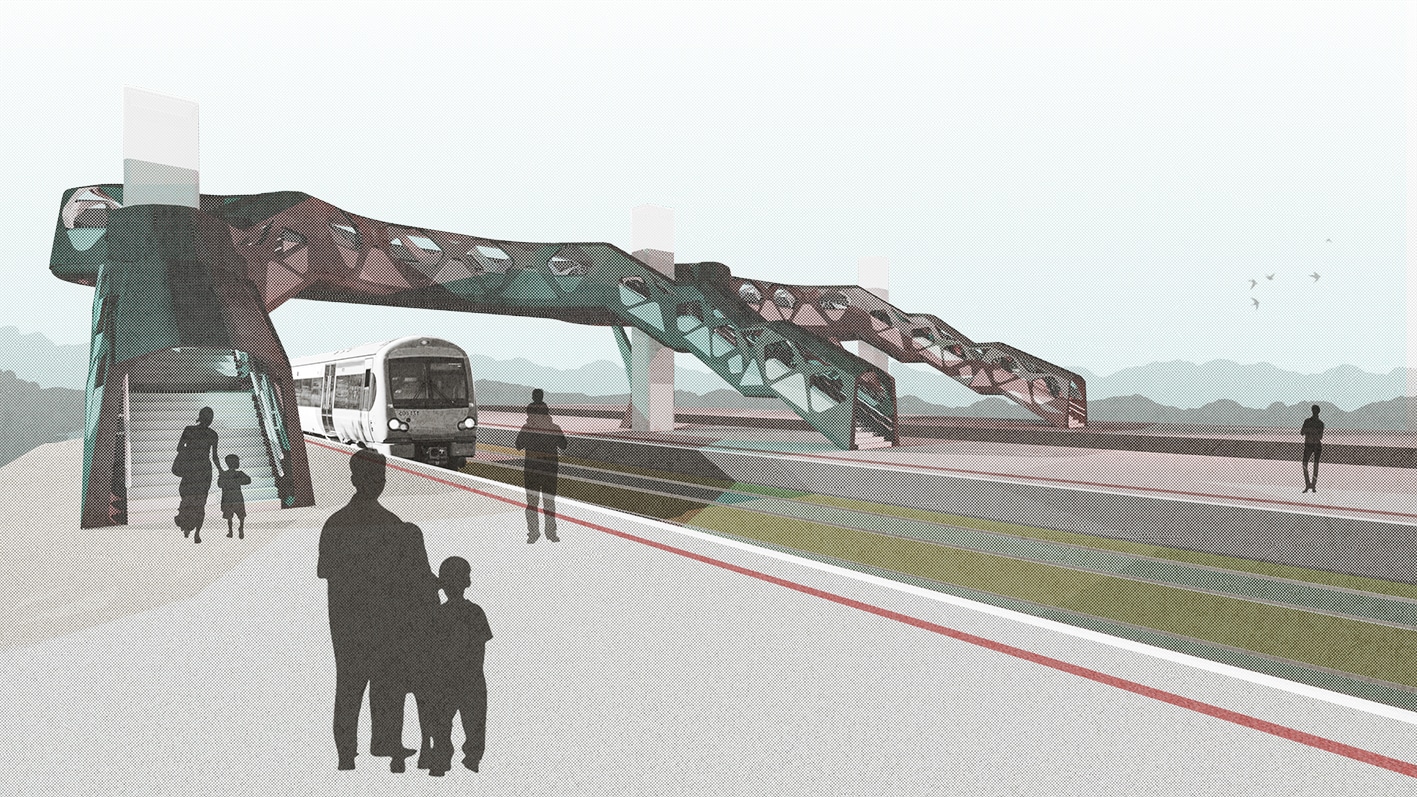

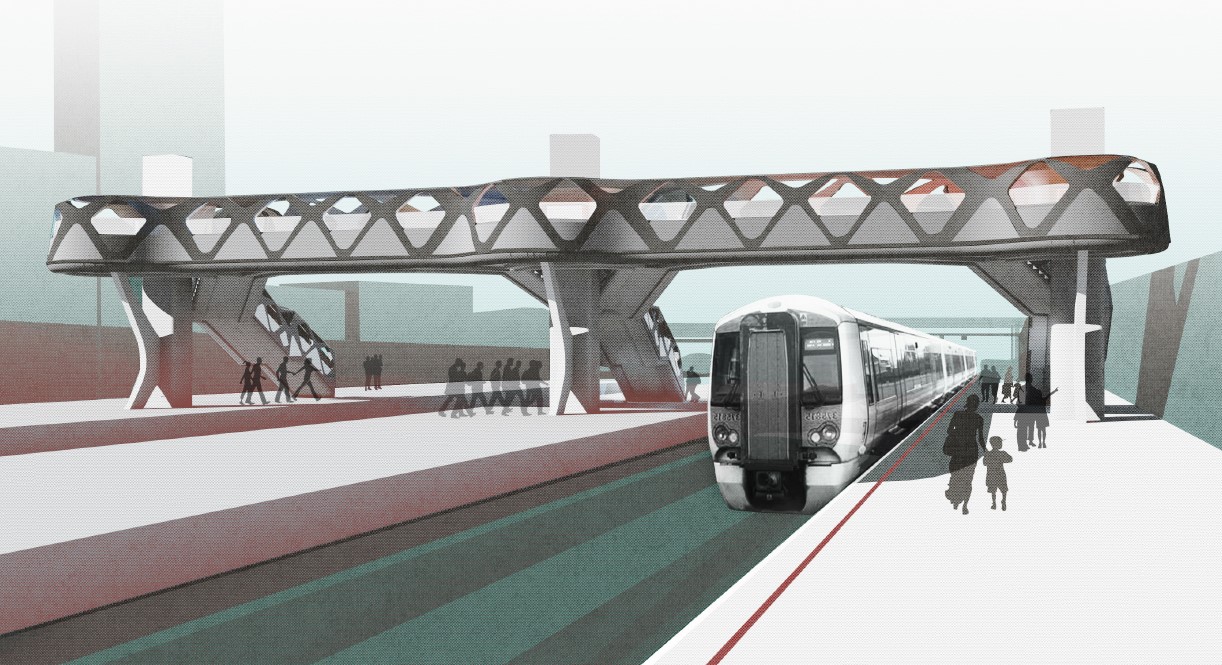

Current Network Rail footbridge designs are practical but utilitarian in design and not without their flaws in terms of congestion of flow and visibility, reducing safety and efficiency. Structurally the three main components – bridge, stair, and lift – are separate and independent. Our proposal is to structurally unite these elements, separate lift and stair passenger flows and resolve the various parameters of the footbridge in a coherent, unified and carefully sculpted design.

The form of the bridge evolved from mapping the parameters of the platform, overhead line equipment and bridge requirements to develop a unified efficient, highly flexible and single component structural solution.

Repetition, alignment and proximity of the structural elements creates unity in the design. GRP (glass fibre reinforced polymer) with uni-directional carbon fibre reinforcement is proposed as the main material for

its excellent properties of lightness, extremely low maintenance, high durability, repeatable moulding and monocoque structural properties.

The structural ethos is to create a simple monocoque structure to span across the railway. This utilises the material extremely efficiently, with high stiffness uni-directional carbon fibre used to reinforce the monocoque along lines of high stress. GRP (lower modulus and lower cost) is used to create the remainder of the tube and to fulfil all the functional requirements.

The structure will be fabricated using techniques from the yacht building industry. A female mould for the various segments will be created with carbon and glass fibre laid up inside, impregnated with resin and cured in an autoclave. A foam core will be used to separate the thin layers of fibre to create efficient structural sections. Dynamic excitation will be controlled by using the entire depth of the section as a stiff, structural U-frame.