© 2020 Cake Industries. All rights reserved.

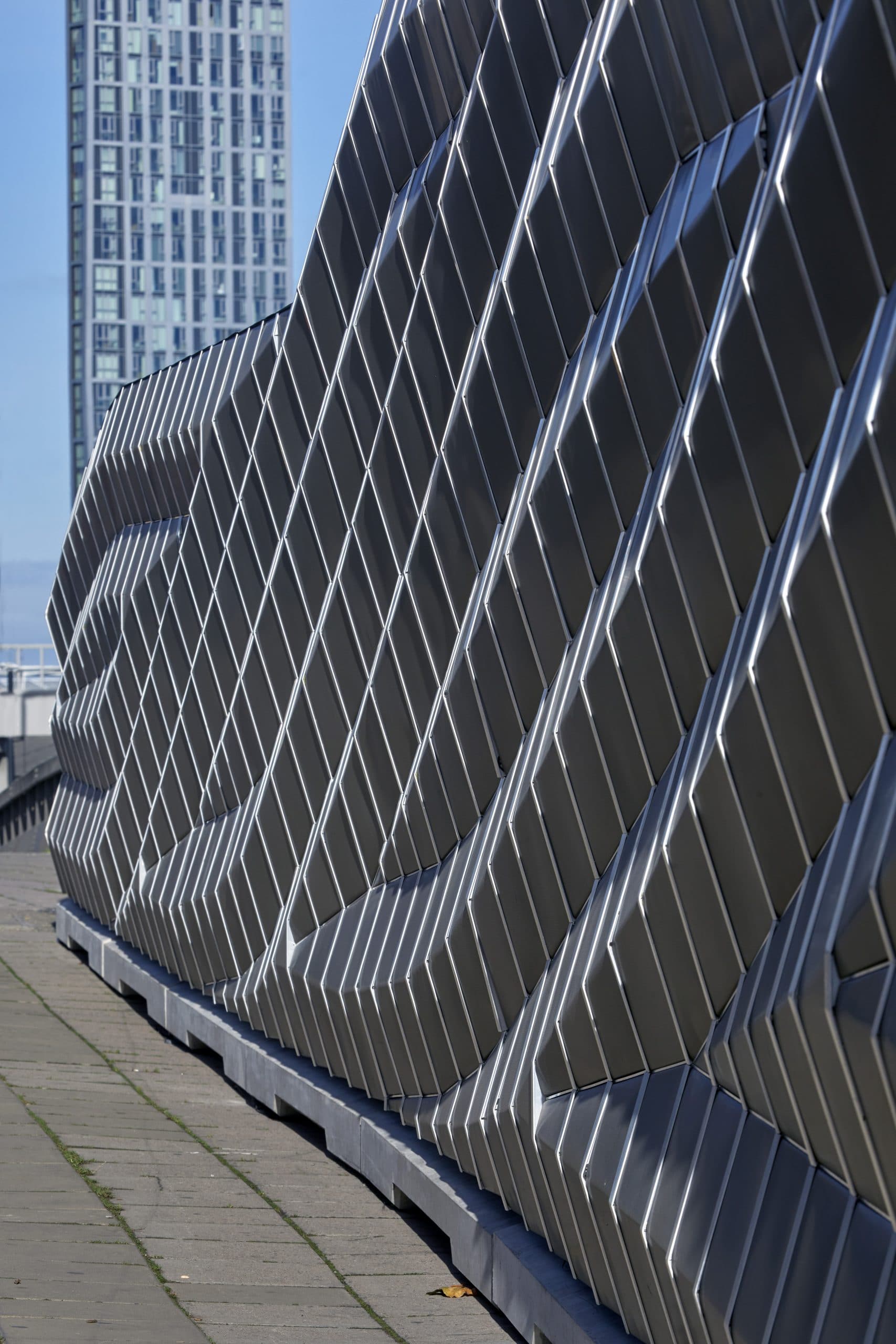

Acoustic Barrier, Bromley-by-Bow

Cake Industries were appointed by Poplar HARCA and TfL to prototype, engineer and fabricate a sculptural acoustic barrier.

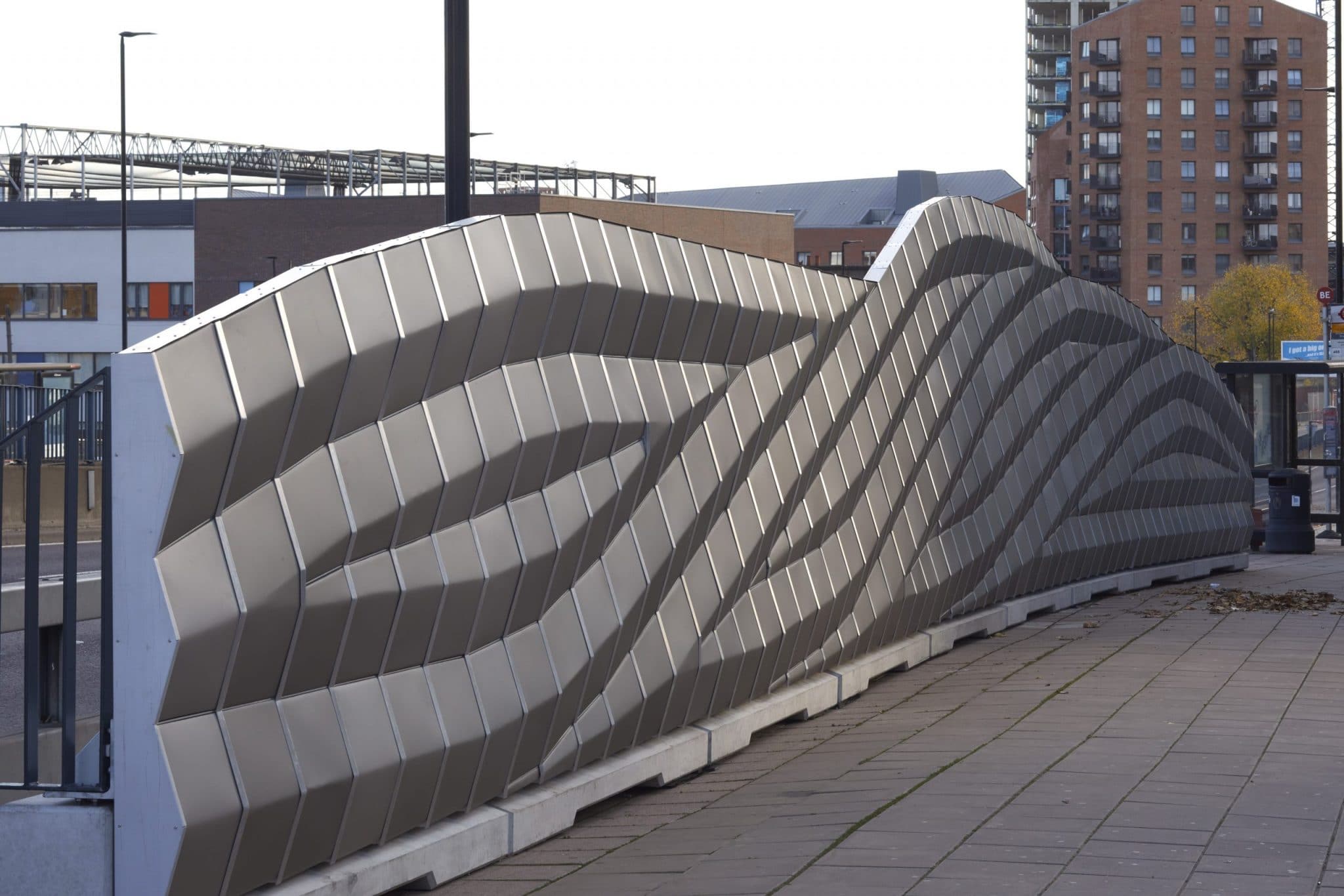

Both public artwork and acoustic shield, the innovative noise barrier has been designed for a busy stretch of the A12 in Bromley-by-Bow, east London.

The installation marks the first UK use of an innovative new type of acoustic panels in a construction aimed at reducing people’s experience of noise pollution. The striking sculptural design turns a civil engineering project into a memorable public artwork.

The design and construction team was led by architects Beep Studio, in collaboration with Expedition Engineering, Cake Industries, Echo Barrier, and Power & Line.

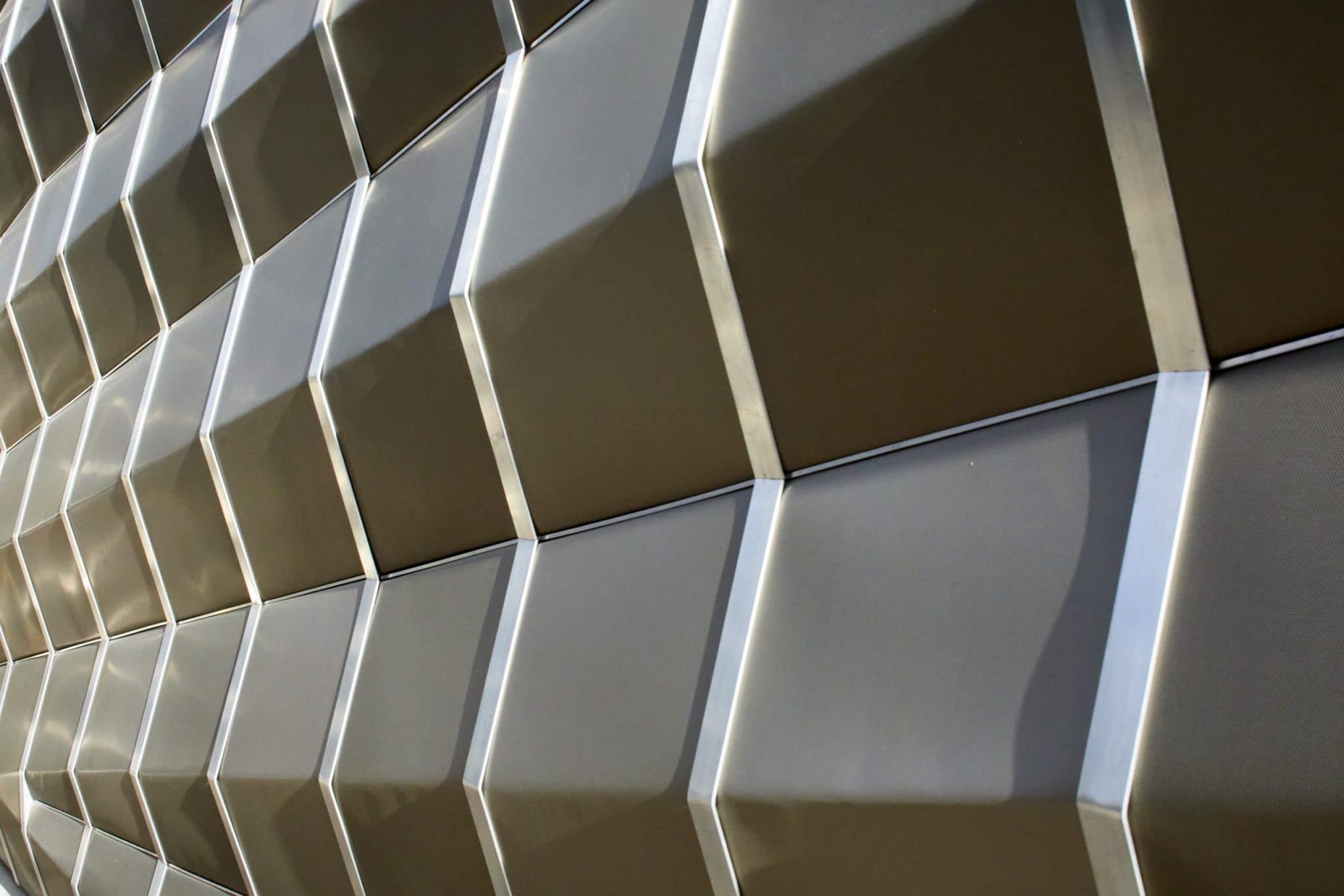

Drawing inspiration from the nearby waterways, the artwork’s geometry is one of folded surfaces and flowing lines. The folds add stiffness, texture, and interest, and this is further enhanced by the reflective material, which picks up fluctuations in light over the course of the day and accentuates the relatively low relief of the sculpture. Surface anodising provides soft and subtle colour.

The barrier is almost thirty metres in length, and reaches a peak height of three metres in front of Jefferson Plaza, where the acoustic effect has the greatest impact.

Most acoustic treatments reduce noise by using soft or textured surfaces to absorb vibrations. The ‘Silk Metal’ system used here is intended to work differently: An aluminium sheet perforated with tiny holes less than a millimetre in diameter forms the front face of a closed box. As sound waves hit the sheet it starts to vibrate, forcing air trapped in the box through the perforations: the resulting friction slows the passage of air, which in turn reduces the vibration of the sheet, and echoing and reverberating sound.

The barrier is formed from over 60 of these sealed cassettes, all of which absorb noise generated by the road through friction, ultimately dissipating this sound energy as heat.

Each cassette in the assembly is linked together into larger groups, which in turn are mounted to a carefully articulated concrete footing. These footings require no permanent fix to the highway and can be removed through a simple crane lift.

This is the first external use of this kind of acoustic baffle in the UK, and brings this innovation to the public realm to enhance the area for people walking and cycling in the area.

Beep Studio won the noise barrier commission through competitive tender in 2016. The installation is the first public UK test of the ‘Silk Metal’ product, with noise levels, pollution levels and public perceptions being monitored by the University of East London. Should the project prove successful a larger product roll out is possible, subject to further testing.

63 uniquely folded aluminium cassettes were fabricated to form the backbone of the barrier. A parametrically defined computer model was created to automatically generate the bespoke cutting patterns needed for each cassette.

The simple structural solution designed by Cake Industries enabled the flowing geometry to be generated from laser cut pieces, and careful consideration of adjustability and tolerance allowed these cassettes to be bolted onto concrete footings sitting on the pavement.

The cassettes form a mould that was clad in ‘Silk Metal’ by craftspeople at Cake Industries. An extensive series of prototyping and testing was used to prove the concept, before the design was signed off for manufacture. The fabrication design and assembly was considered carefully to maximize quality and repeatability, and is now set up for future iterations of the scheme. The ‘Silk Metal’ material which the barrier is made from means it is the first of its kind in the UK. Its unique design intends for the installation to also function as a public artwork.

Noise levels on the A12, which sees more than 15 million vehicles moving along it every year, have been found to consistently exceed 78 decibels by The University of East London (UEL). This puts the A12 in the most severe category for noise pollution, according to the World Health Organisation and the Department for the Environment

Based on a specialist micro-perforated aluminum material, the barriers were designed as cassette units that could be installed quickly to create a beautiful environment for pedestrians beside busy roads.

The project was featured in the New London Architecture exhibition “Future Streets”.

Architect: Beep Studio (www.beepstudio.co.uk)

Conceptual Structural Design: Expedition Engineering

Installation: Power and Line

Silk Metal: Echo Barrier

Client: Poplar HARCA

Funding: TfL and London Borough of Tower Hamlets

Acoustic Monitoring: University of East London

All images taken by Edmund Sumner